Engineering

Concurrent Mechanical & Electronics Design Serveral engineering companies valuate E³.series as a very good solution. Modelling & structuring plant specific true object oriented database within a multiuser environment (database including all plant equipment, drawings and relevant technical docs.), combined with E³’s unique quality control offers electrical & process engineering departments an efficient tool. Solutions for […]

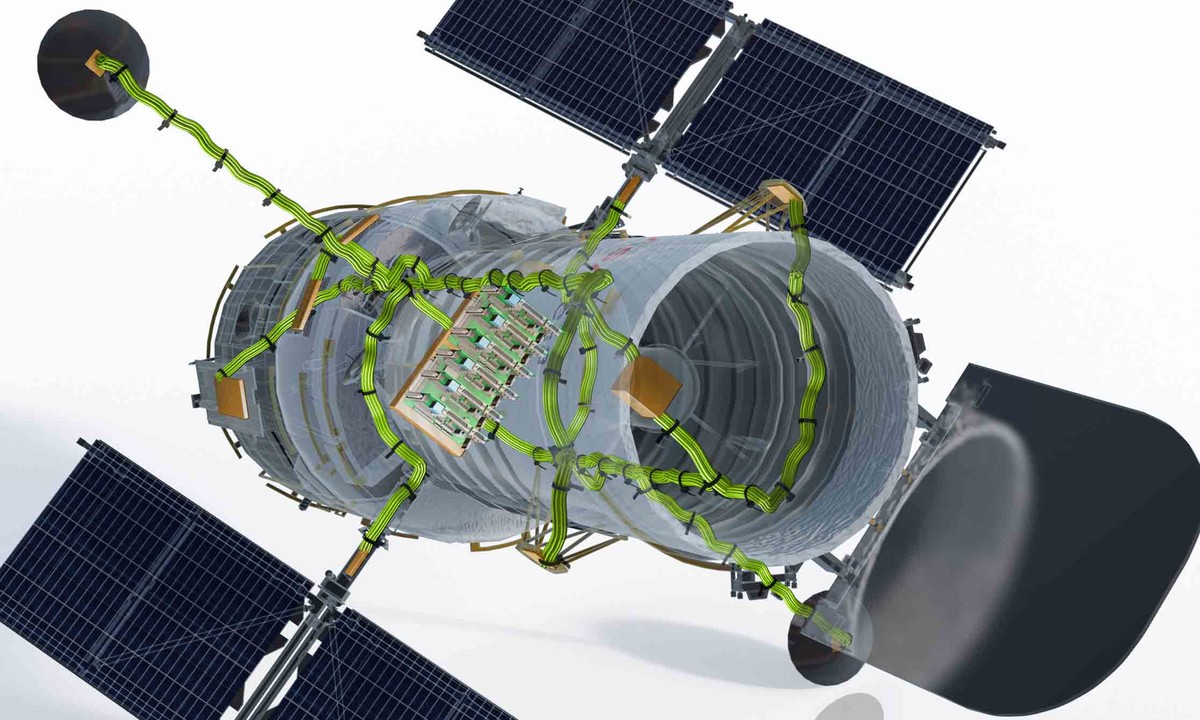

Concurrent Mechanical & Electronics Design

Serveral engineering companies valuate E³.series as a very good solution.

Modelling & structuring plant specific true object oriented database within a multiuser environment (database including all plant equipment, drawings and relevant technical docs.), combined with E³’s unique quality control offers electrical & process engineering departments an efficient tool.

Solutions for integration between ECAD and MCAD also make E³.series a good choice for collaboration across departments.

Download whitepaper: Concurrent Mechanical & Electronics Design (PDF)

Beneficial features

- one system; – ‘overall’ as well as ‘detailed engineering

- same object may be represented in different ‘type of documentation’ (; block-, single line-, wiring-, termination-, GA- diagram, etc.)

- assure quality in all document types changing object once

- communication to engineering databases and/or excel

- automatic generation of documentation from available sources (;excel, configurators, eng.databases, etc.)

- reuse of documentation from several vendors (;different formats)

- manage all plant cables (become ‘master of all cables’)

- multiuser environment

- simultaneously multi diciplin engineering (;Electrical Engineering & Hydraulic/Pneumatic)

- import General Arrangement, place equipments physical view with direct link to schematics

- direct access to datasheets and certificates relevant to all equipment included

- export final documentation in any accepted format (;pdf, dwg/dxf, dgn, tif, etc.)

Oops! We could not locate your form.